Introduction:

In today's technologically advanced world, where electricity plays an indispensable role in our daily lives, the demand for efficient and reliable power transmission has never been higher. Power cables are the lifelines that connect power generation sources to homes, businesses, and industries. However, in certain environments where extreme temperatures and heat are prevalent, the performance and safety of conventional power cables can be compromised. insulated sheathed power cable is where heat resistant power cables come into play, ensuring the uninterrupted flow of electricity even in the harshest conditions. In this article, we will explore the importance, characteristics, and applications of heat resistant power cables.

1. Understanding Heat Resistant Power Cables:

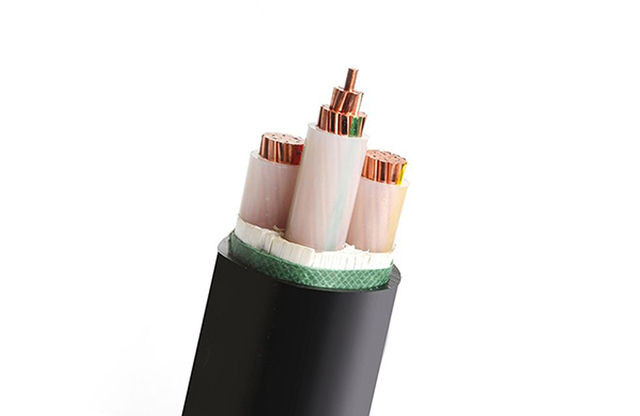

Heat resistant power cables, also known as high-temperature cables, are specifically designed to withstand elevated temperatures without any significant degradation in their electrical and mechanical properties. These cables are engineered using specialized materials and construction techniques that enable them to resist the damaging effects of heat, ensuring reliable power transmission in extreme environments.

2. Characteristics of Heat Resistant Power Cables:

2.1 Temperature Rating:

The most crucial characteristic of heat resistant power cables is their temperature rating. These cables are classified based on the maximum temperature they can withstand continuously without suffering any adverse effects. Common temperature ratings include 90°C, 105°C, 125°C, 150°C, and even higher. The selection of the appropriate temperature rating is essential to ensure the cable's longevity and prevent any potential hazards.

2.2 Insulation and Jacket Materials:

Heat resistant power cables employ advanced insulation and jacket materials that exhibit excellent thermal stability and resistance to heat-related degradation. Common insulation materials for high-temperature cables include cross-linked polyethylene (XLPE), ethylene propylene rubber (EPR), and silicone rubber. Similarly, jacket materials like chlorinated polyethylene (CPE), neoprene, and fluoropolymers are used to provide additional protection and resistance against heat, oil, chemicals, and other environmental factors.

2.3 Flame Retardancy:

Fire safety is a critical aspect to consider when working with power cables. Heat resistant power cables are engineered to have excellent flame retardant properties, minimizing the risk of fire propagation in case of a fault. This ensures the safety of personnel and property, especially in applications where flammable substances are present.

2.4 Flexibility and Durability:

Heat resistant power cables are designed to be flexible and durable, allowing easy installation in various configurations. The cables maintain their mechanical integrity even at elevated temperatures, ensuring long-term performance without any compromise on quality or safety.

3. Applications of Heat Resistant Power Cables:

Heat resistant power cables find extensive applications in a wide range of industries and environments where high temperatures are prevalent. Some notable applications include:

3.1 Power Generation and Distribution:

In power generation facilities, such as thermal power plants, nuclear power plants, and solar farms, heat resistant power cables are used to transmit electrical energy from generators to transformers and distribution networks. These cables ensure efficient power transmission, even in areas where temperatures can exceed the capabilities of conventional cables.

3.2 Industrial Processes:

Industries such as steel manufacturing, glass production, cement plants, and chemical processing often involve high-temperature operations. Heat resistant power cables are essential for powering equipment, machinery, and instruments in these harsh environments, ensuring uninterrupted production and minimizing downtime.

3.3 Oil and Gas Industry:

The oil and gas industry operates in extreme conditions, including offshore platforms, refineries, and petrochemical plants. Heat resistant power cables are utilized to power critical equipment, control systems, and lighting, enabling safe and reliable operations even in high-temperature environments.

3.4 Automotive and Aerospace:

In automotive and aerospace applications, heat resistant power cables are used to supply power to various electrical systems, including engines, lighting, and avionics. The ability of these cables to withstand high temperatures and harsh conditions is crucial for the reliable and safe operation of vehicles and aircraft.

4. Standards and Regulations:

To ensure the quality and safety of heat resistant power cables, various international and regional standards and regulations have been established. These standards define the technical specifications, performance criteria, and testing procedures that manufacturers must adhere to. Some widely recognized standards include the International Electrotechnical Commission (IEC) 60245, IEC 60331, and Underwriters Laboratories (UL) 44.

5. Conclusion:

Heat resistant power cables play a vital role in ensuring uninterrupted power transmission in environments with high temperatures and extreme conditions. These cables are designed with specialized materials and construction techniques to withstand elevated temperatures without compromising their electrical and mechanical performance. With their flame retardancy, flexibility, and durability, heat resistant power cables find applications in various industries, including power generation, industrial processes, oil and gas, automotive, and aerospace. Adherence to international standards and regulations ensures the quality and safety of these cables, making them a reliable choice for critical power transmission needs.